Why Fusion 360 Is the BEST for Woodworking

Is Fusion 360 The Best Design Software For Woodworking?

After using Fusion 360 for over a year to design my woodworking projects here’s what I’ve discovered about the program and why I think more woodworkers should be using it.

I’m confident Fusion 360 is the best woodworking design software available because it is built around parametric design. This feature allows you to quickly change the dimensions of a finished model, or individual components in a model, just by changing a value. That means after your model is complete if you change your mind on the size or material thickness you don’t have to redraw your model!

With Fusion 360 you can easily design, test, modify, and see your woodworking projects in 3D before you ever have to cut a piece of wood.

What is Fusion 360

Fusion 360, created by Autodesk, is one of the most powerful and versatile CAD programs out there for students, hobbyists, and professionals alike.

With Fusion 360 you can design and prototype models in both 2D and 3D, render high-resolution mockups, create detailed plans and schematics, even produce video animations of your model and its assembly.

It’s commonly used in the 3D printing circle, as well as in the new and growing field of at-home, small scale, CNC design and programming.

Although the software needs to be installed on your computer, it is cloud-based so you can share and collaborate on your designs from anywhere with an internet connection which is a plus.

“But what’s the big deal? That sounds exactly like all the other CAD/CAM programs out there?”

On the surface, yes, it may be hard to differentiate Fusion360 from its competitors, that is, until you understand parameters and how Fusion uses them.

Easily Adjust Project Dimensions with Parameters

Let’s pretend we’re designing a hanging tool cabinet with swing-out doors in a different program like Sketchup. Its overall length is 48” tall, 36” wide, and 11.25” deep. Let’s pretend that after we’ve finished up the design we decide that it’s too tall, too wide, and needs to be deeper.

Check out how quickly you can change dimensions with related components adjusting!

Pretty much our only choice would be to redesign the whole project or painstakingly push and pull the different components until we’ve achieved the new dimensions.

With Fusion 360, if we set up our model correctly, all we would need to do is open the parameters window and change the height, width, and depth values. Within less than a second Fusion will have adjusted not only those dimensions but ALL the other parts of the cabinet to match.

The reason we can do this with Fusion 360 is that we can set up and define parameters for the model - “CabinetDepth = 12 in.” So when that value changes, Fusion 360 will change any dimension labeled “CabinetDepth” to match.

You can even do equations in Fusion. Let’s say you want your cabinet width to be 2.5X whatever the depth is. Since we already have the depth defined with a parameter we can set up a new parameter like, “CabinetWidth = CabinetDepth x 2.5.” Now whenever the value for the depth is changed, Fusion will also adjust any dimensions under the “CabinetWidth” parameter.

I can’t stress enough how powerful this feature is, and how many times it’s saved my sanity.

Create Detailed Plans

So you’ve designed a beautiful woodworking project model but now what? How do you build it? How do you find out all of the different dimensions of your project?

With Fusion 360’s drawing feature you can quickly and easily create very detailed plans that include dimensions, cutaway views, annotations, line drawing or shaded and colored, multiple angle views, and more before exporting them as a PDF to print.

But the best part is that the plans will reference your model AND the model’s parameters. That means that if the length of a component changes in the model it will update in the plans.

Animate Joints

One key advantage when designing furniture can be the ability to visualize how the piece will look, work, and function. That includes any moving parts that the project may have such as doors and drawers.

With Fusion 360 you can easily define joints and motion to check if your design will function the way you want it to even before you build it!

Example: you’re designing a wooden lamp that utilizes a scissor extension mechanism like the one in this video. You could use Fusion 360 to design the lamp and then with the Assemblies/Joints feature you could test to make sure the scissor extension will not only work the way you want but extend or contract to the dimensions you want.

Test Structural Strength

This is a feature that I haven’t personally tested in Fusion, but I am aware of it and how powerful it can be.

Through their materials window Fusion 360 allows you to add structural attributes to the different parts of your design and then test how those parts will react to different levels of load, torque, pressure, temperature, etc..

You could design a bed frame, define the material used, and then test to make sure the stretchers are thick enough or wide enough to support however many pounds you want to test. Fusion 360 will even show you the weak points in your design and where the majority of the stress is being applied.

To be fair, this isn’t the easiest feature to use in Fusion as there are so many variables in wood and its tensile/load bearing weight that it would be a liability for companies to provide accurate stress simulations. However, it is possible to manually input values and test.

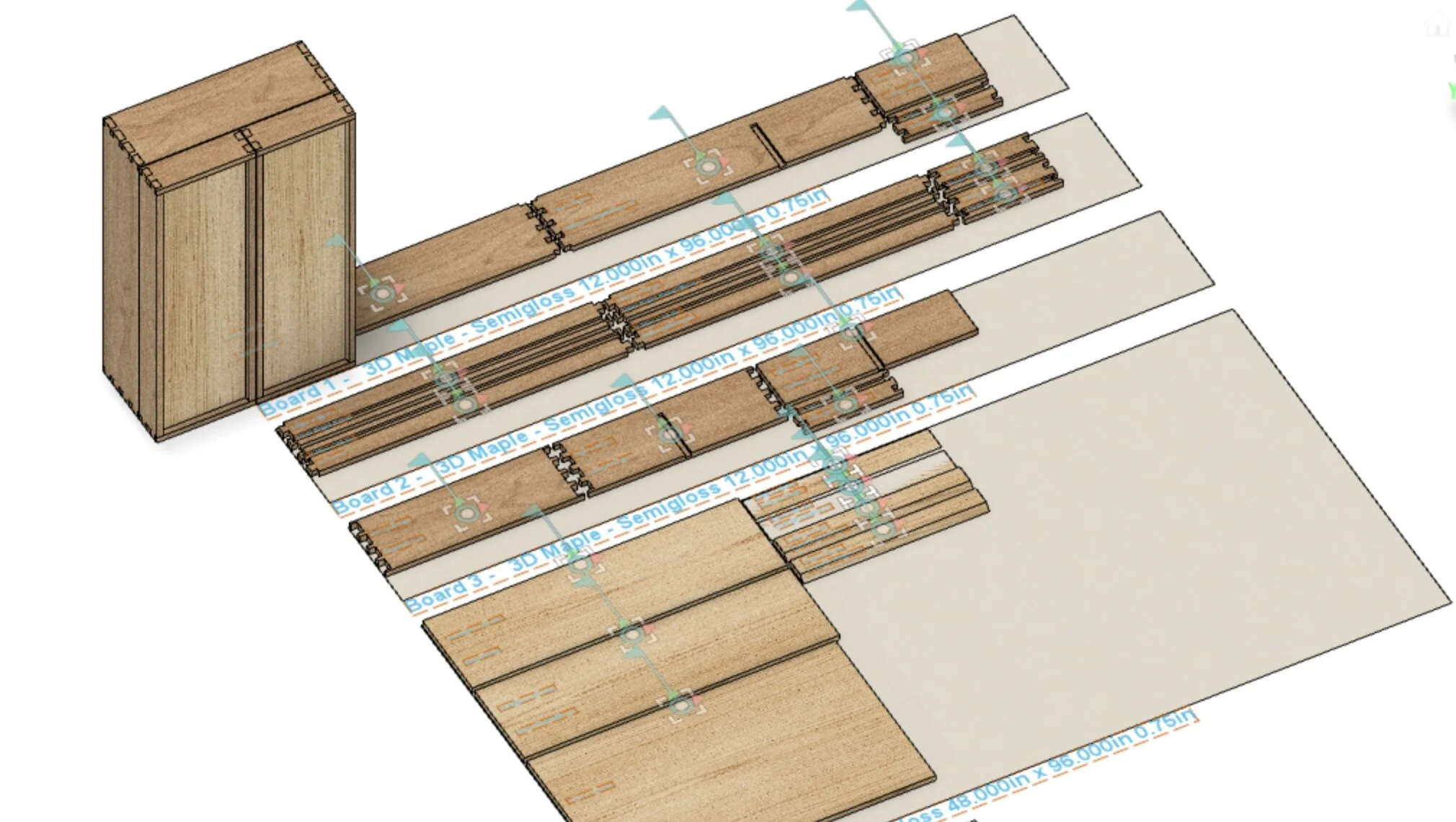

Cut Lists and Flat Maps

Fusion 360 has its own marketplace of approved 3rd party add-ons that enhance the software’s features. By adding in a few 3rd party apps you can easily make Fusion 360 an even more dynamic woodworking design powerhouse.

The one add-on that I like and use the most is MapBoards.

After entering your material dimensions, MapBoards takes your model and finds the most optimal way to layout your pieces to cut and how many boards you’ll need. Conversely, you can use the same tool to figure out exactly how much material you will need for a project which is a great feature to have.

You can even adjust the spacing of the components, account for kerf thickness, and decide if you’d like to optimize for rip cuts or crosscuts.

It’s FREE!

For the most part.

AutoDesk (the maker of Fusion 360) has certain criteria you must meet in order to qualify for a free version of their software, but most people in the woodworking world will meet those criteria.

Fusion 360 is free to:

Students

People using the software for personal use

Hobby businesses (grossing less than $1,000/year)

People creating YouTube, blog, or other web content (some restrictions apply)

For more info on if you qualify for a free subscription to Fusion 360 check out this information here.

How To Get Started With Fusion 360

With all of these features combined, Fusion 360 is a clear no-brainer as my go-to woodworking design software and I think that after you get the basics of the program down, you’ll feel the same way too.

If you’re ready to sign up for Fusion 360 and completely change how you design and build furniture click here.

For a full list of what I think are the best free resources to learn Fusion 360 for woodworking, take a look at the following article:

Let me know in the comments below what the first thing you’re going to design with Fusion 360 is!